Surface Cleanliness Standards: Preparation adheres to recognized industry standards, such as those outlined by:

Determined using Testex replica tape or a profilometer, ensuring the profile matches coating manufacturer specifications. Typical profiles range between 1.5 to 4.5 mils depending on the coating system and substrate.

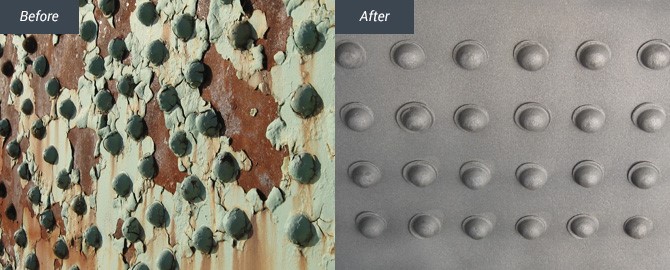

Surfaces are inspected post-preparation for cleanliness, profile depth, and presence of residual contaminants. Methods include visual inspection, salt contamination testing, and surface profile measurement.

Dust collection systems and enclosures are used to minimize environmental impact. Personal protective equipment (PPE) is mandatory for workers. Compliance with environmental regulations (e.g., dust and waste management) is strictly observed.